In more recent times however, with the mainstreaming of the internet and the development of various courier services, the act of procuring tools and necessities have drastically changed. With delivery-by-your-doorstep being a common practice nowadays, it became easier for people to obtain their supplies even without leaving the comforts of their homes. There is, however, another piece of technology currently brewing that would revolutionize the whole way procuring items. This technology would be 3D printing.

3D printing is just what it sounds like: printing three-dimensional objects using a specialized form of printer. It acts similar to your normal, everyday printer. However, instead of simply spraying ink on a blank sheet of paper, 3D printing uses various materials such as resin and other synthetic materials to print out three-dimensional, usable objects. Yes you heard it right, 3D printed objects are not ornamental, they can be used! Need a specific-sized spanner but you're too lazy to go out to the hardware store to buy one? No problem! Just download a specific schematic detailing your spanner, fire-up your 3D printer, press a button and voila, a usable spanner that fits your desired size!

| |||||

| It's that simple. Image obtained via screenshot of http://www.youtube.com/watch?v=jQ-aWFYT_SU&noredirect=1 |

This whole technology however is not really new. Its history can be traced back to as early as the mid 1980s. In 1984, Charles Hall, co-founder and current vice-president of 3D Systems, managed to produce a painting process that enables three-dimensional objects using data from a computer. He called this whole process as stereolithography.

In its early years, the technology mostly stayed within the industrial sector of society due to the high costs of the materials and the printers. 3D printers were used to print out parts of automobiles, aircraft and other forms of machinery. It is not until the late 2000s that the technology managed to enter the mainstream market. Various companies such as MaketBot, RepRap, Cubify and Stratasys have made their own 3D printers, marketing and selling them to the consumer market.

| |||

| This is an example of a consumer-based 3D printer. Printers such as these used to cost around $20,000 when it first came out of the market. To put it in perspective, at that price, it's more expensive than a Toyota Corolla. Image from http://makerbot-blog.s3.amazonaws.com/wp-content/uploads/2013/06/MakerBot_Replicator2_Front_View-700x466.jpg |

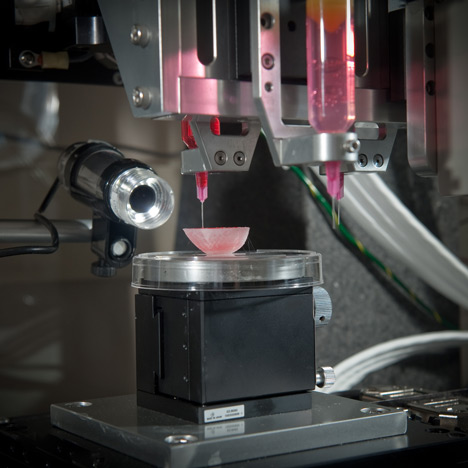

Various advancements have also taken place using this technology. In the field of biomedical technology, 3D printing is also being utilized. North Carolina's Wake Forest Institute of Regenerative Medicine is using this technology in attempting to 3D print organs. Yes, you heard that right, organs. By making use of a biodegradable mixture with a blend of human cells, it would not be far from the future when we can replace a part of our body with an object churned out of a 3D printer. This innovation is still currently in the pre-clinical stages of development however and would take a couple of more years before the whole technology becomes usable. Nevertheless, we're getting somewhere.

| ||

| That right there is a kidney being 3D printed. A prototype of course. Image from: http://static.dezeen.com/uploads/2013/05/dezeen_Print-Shift-3D-printing-and-health_4a.jpg |

However, what does this technology mean for the world? What would change? Of course the courier and market industry would be severely affected but what about the other side of the coin? What about the consumers? What would happened to us?

For the everyday consumer this technology would definitely spell an easier time of obtaining much needed tools and objects. And with the sprouting of internet-based databases full of ready-to-download schematics of 3D objects, things are even much easier than before.

|

| Websites such as Thingiverse.com is a database full of schematics ready for 3D printing. |

There are also some issues rising with the advancements of 3D printing. Copyright and intellectual property are one these issues. One of the bigger issues is of legal and safety, however. What would happen to the world if things such as gun parts and mechanisms would be readily available to everyone? A scary thought perhaps, but it's a reality.

|

| That right there is an assault rifle with a 3D printed part. Image from: http://static.dezeen.com/uploads/2013/05/dezeen_How-3D-printed-guns-and-drones-are-changing-weaponry-and-warfare-2.jpg |

3D printing is rapidly evolving. If I would be so bold and be allowed say, I predict that this technology would go full mainstream within two to three years from now. It wouldn't be long from now, when each household would house a 3D printer or two just as they would with a normal, ink-jet printer.

Here in the Philippines, would you be surprised if I tell you that 3D printers have also started to spread? Just go ahead and visit CD-R King's website and you'll be in for a treat: you can very well purchase a 3D Printer of your own for the price of Php 100, 000.00! Expensive coming from a company/store that sells stuff that mostly guarantees a week or two of shelf life but hey, at least it's a start right?

0 comments